Time:2021-08-12 Click:503

ANALYSIS OF THE EFFECT OF TRANSFER PRINTING ON THERMAL TRANSFER POWDER COATINGS

This paper explores the effect of polyester/TGIC, polyurethane/B1530 system and additives on the surface effect of woodgrain transfer. By selecting different acid value (hydroxyl value) of polyester, auxiliary agent, wood grain transfer powder leveling, clarity and transfer tearing paper is difficult, solve the transfer paper in the process of thermal transfer polyester powder coating production, mimeograph And the problem of insufficient clarity.

1. INTRODUCTION

Powder coatings are environmentally friendly coatings during the production and coating process, such as solvent release, less pollution, easy recycling, and high utilization. With the continuous improvement of process conditions and the continuous improvement of market requirements, powder coatings have developed rapidly in recent decades due to their own advantages.

Thermal transfer, also called thermal sublimation, is a process of transferring a pattern on a transfer paper to a substrate by using a thermal transfer device to heat it to a set temperature in a short time. The thermal transfer powder coating can provide a colorful and layered transfer pattern. After the sublimation of the wood grain paper (film), the ink can penetrate into the cured coating 30-50 μm, and the transferred coating is durable, not There will be shedding, cracking and fading.

At the same time, the thermal transfer powder coating does not change the original coating properties (such as hardness, scratch resistance, impact resistance, salt spray resistance, acid and alkali resistance, aging, etc.), and has been obtained in recent years in aluminum profiles. A wide range of applications provide a rich decorative effect for architectural aluminum profiles and furniture decoration.

At present, thermal transfer polyester powder coatings are mainly divided into polyurethane wood grain powder coating and polyester/TGIC. Polyurethane powder coatings have high cross-linking density, full-coating after curing, high hardness, good leveling and weather resistance, easy to tear paper after transfer, clear pattern, and skin feel.

However, the disadvantage is that it is expensive, and the polyurethane wood grain powder is applied in low gloss, and the sticky paper is easy to be printed on the high gloss wood grain powder, probably because the high gloss polyurethane wood grain powder has a small amount after curing. The base and ink have a repulsive effect.

The wood grain powder of polyester/TGIC curing system has lower price and wide application, but the hardness after solidification film formation is generally 1H~2H. Such powder often encounters poor leveling and is not easy to tear when used for thermal transfer. The problem of unclear patterns on paper or transfer. In this paper, by comparing and screening polyester resins with different acid values (or hydroxyl values), it is optimized to select polyester with high reactivity and good flatness, and it is difficult to solve the problem of tearing paper with wood grain powder. The problem of a lot of oil on the surface of the layer.

2. TEST PART

2.1 The effect of resin on the transfer effect of wood grain

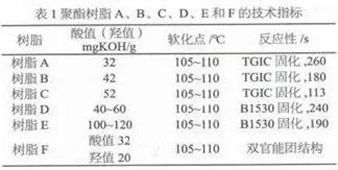

The experiment selected three different acid value polyester resins (resins A, B, C) and a low hydroxyl value (resin D), a medium hydroxyl value polyester resin (resin E), one end via a base group Bifunctional polyester resin (resin F). Their technical indicators are shown in Table 1.

Other major materials and equipment: triglycidylisocyanurate (TGIC), B1530, white powder, barium sulfate, powder coating additives (leveling agent, brightener, benzoin, wax powder, etc.). Equipment includes: twin-screw extruder, high-speed universal pulverizer, electrostatic spraying equipment, high-temperature oven, heat press machine, etc.

2.2Preparation of thermal transfer powder coating

According to the formula designed in Table 2, the polyester resin, curing agent, auxiliary agent and pigment filler are accurately weighed, fully pre-mixed, melt-extruded, cooled and crushed, and then ground by a high-speed pulverizer. Thermal transfer powder sample. Finally, the heat transfer was performed by a heat transfer machine to obtain a template.

Table 1 shows that the higher the acid value (hydroxyl value) of the resin, the higher the reactivity of the resin. From the comparison of the experimental groups of Table 2, the higher the acid value (hydroxyl value) of the resin, the higher the crosslinking density of the coating, and the higher the hardness of the coating after curing. In general, the higher the crosslink density of the polyester resin used for woodgrain transfer, the higher the hardness, the texture that is transferred is not only clear, the paper is easily torn, and the printing of the coating after transfer is greatly reduced.

However, as the acid value of the resin becomes higher, the amount of the resin and the reaction-cured TGIC (B1530) is increased, the gelation time is shortened, the reactivity is improved, the leveling of the coating is deteriorated, and the cured coating is brittle. Large, poor mechanical properties and other shortcomings. Therefore, in the case of ensuring a high crosslink density, high leveling property and hardness of the powder, it is possible to use two resins of high and low acid value (hydroxyl value) to prepare a wood grain powder with good transfer effect.

2.3 Two different acid value (hydroxyl value) resin compounded to prepare wood grain powder

Use two different acid value (hydroxyl value) resin combination to make the coating have higher crosslink density and hardness, and ensure the coating after curing.

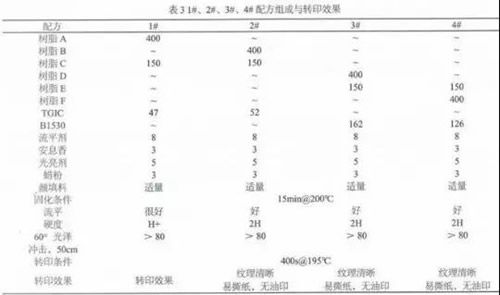

The layer has excellent leveling and tearing effect, reducing the presence of oil marks after transfer. The formulation of the design is shown in Table 3.

Experiments 2 and 3 show that the hardness of wood grain powder made by formula 1# is higher than that of single component, indicating that the addition of high acid value resin C improves the crosslinking density of the coating after curing, so that the coating is coated. The hardness of the layer is improved, the transfer effect is improved, but there is still a phenomenon of printing after transfer, which is related to the structure and reactivity of the resin A itself, the acid value of the resin A itself is low, and the crosslink density of the cured coating is low. Lower, even if high acid value resin C is added, it cannot be 100% cured.

Formulation 2# After adding high acid value resin, the transfer effect is improved, the leveling property is good, and the transfer without oil mark exists. Adding a part of the hydroxyl value of the polyurethane in the formula 3#, 4# improves the sticking of the low-value polyurethane after curing. Experiments of 2 and 3 show that the addition of high acid value (hydroxyl value) resin can effectively improve the crosslink density and hardness of wood grain powder, thereby improving the transfer effect of wood grain powder.

2.4 Effect of additives on wood grain transfer

In the design of wood grain powder formulations, additives are often added to improve the performance of the coating. Commonly used additives include leveling agents, wetting agents, benzoin, curing accelerators, wax powders, and the like. Leveling agents and wetting agents play a role in improving leveling. Studies have shown that the leveling agent and the wetting agent will migrate to the coating after the coating is cured. It indicates that the excess will affect the transfer effect, so that the coating is easy to leave a mimeograph after the transfer, so add appropriate amount in the formula design. . Benzoin mainly plays a role in degassing in the formulation, and its effect on wood grain transfer clarity is not significant.

A certain amount of wax powder is usually added to the aluminum profile powder coating to improve the scratch resistance of the coating and achieve a smoothing effect. The surface contact during the thermal transfer process is a physical process, so the influence of the interfacial tension of the wax powder on the transfer effect is large. Experimental data from related literature indicates that the smaller the surface tension of the wax powder, the easier the transfer is to tear the paper. However, the addition of wax powder will affect the sharpness of the texture, so the amount of wax powder should be appropriate when designing the wood grain formula.

In order to improve the reactivity of the wood grain powder polyester, the coating layer can be sufficiently cured, and a certain amount of a curing accelerator is usually added to the formulation. However, pay attention to the amount of addition, too much will affect the leveling effect of the coating

The transfer effect of the thermal transfer powder coating mainly depends on the reactivity of the resin. The cross-linking density of the coating is large, the hardness is high, the transfer pattern is clear, the paper is easily torn, and it is not easy to leave after printing. In summary, when designing wood grain powder coating formulations, polyester resins with high reactivity and high degree of curing should be selected, or they should be compounded by high and low acid value (hydroxyl value) to ensure higher coating after curing. The cross-linking density has better leveling performance and transfer effect. At the same time, when designing the formula, attention should be paid to the addition amount of various additives to ensure the optimization of the formulation to achieve a good transfer effect.