Time:2021-08-12 Click:415

At present, the surface of the security door on the market is mostly wood grain texture, which has the characteristics of environmental protection, economy, high efficiency and excellent performance, and has obvious advantages. Wood grain transfer is deeply loved by people for its unique decorative effect and beautiful appearance, especially the visual effect of simulated logs. However, due to the unsatisfactory leveling effect of the wood grain transfer bottom powder, the gloss does not meet the requirements and the curing cross-linking is incomplete, and there are many reasons such as glue watermark and residual paper hair after the transfer of the wood grain paper. Usually after the transfer, sandpaper is used for sanding, and the transparent paint is used to cover the light to achieve leveling, the gloss meets the requirements, the grain texture is clearer, and the facade effect is softer. In recent years, with the country's emphasis on environmental protection, environmental protection conditions have become more and more demanding, and oil-based coatings are increasingly restricted due to the high irritating odor and high VOC emissions. Therefore, it is inevitable to change the powder in the security door of the security door.

1、SOLUTIONS

According to the purpose of the varnish described in the preface, combined with the actual situation, the solutions that can be considered are:

1. Improve the leveling property of the base powder and the curing cross-linking density so that there is no glue watermark and no “paper wool” when transferring, so that the surface effect meets the customer's requirements at one time.

2. After the sandpaper for bottom powder transfer is polished, replace the oily transparent paint with a transparent powder that meets the gloss requirement.

3. After the sandpaper for bottom powder transfer is polished, replace the oily transparent paint with a water-based transparent paint that meets the gloss requirements.

At present, water-based industrial paint technology and technology are still not mature, and can not be widely used in security door light. Door manufacturers also basically do not consider this plan. Therefore, this paper intends to explore options 1 and 2:

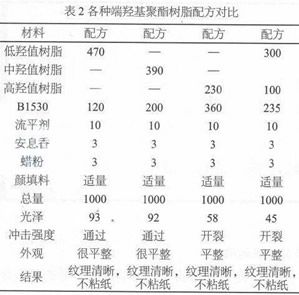

IOption 1: (taking outdoor products as an example) Select a suitable carboxyl terminated polyester resin or hydroxyl terminated polyester resin, and add an appropriate amount of a curing accelerator to ensure the crosslink density of the transfer base powder.

It can be seen from the above experiment that the bottoming powder with good leveling has a relatively long gelation time, and the bottom powder is easy to stick paper; the bottom powder of the non-stick paper has a short gelation time, but the leveling is general.

Therefore, the terminal carboxylated polyester as the transfer base powder cannot meet the requirements of the facade due to the surface effect, and generally cannot be used as a mature product, and the effect of polishing and glazing treatment is better.

The base powder produced by the hydroxyl terminated polyester resin has good leveling property, good tearing paper and clear texture, but it is limited in cost and relatively low cost, especially for low-light products, which limits the widespread use.

It can be seen from the above scheme that the facade which is transferred by using the base powder alone has the problem of poor leveling or high cost, and it is difficult to promote in a short time, so the solution of the bottom powder transfer and the light-transparent powder cover can be considered. . So Option 2 becomes the focus of the solution.

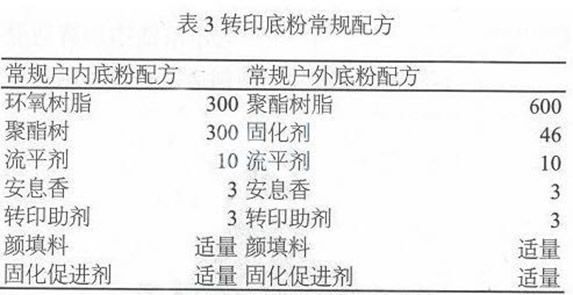

Option 2: Transfer the polished transparent powder after high-leveling indoor or outdoor base powder. Due to the grinding process, the leveling property of the bottom powder and the transfer paper sticking phenomenon are relatively low, and the surface effects such as leveling property and wood grain sharpness after the transparent powder are superior to those of the foregoing process.

After the above-mentioned bottom powder is sprayed, the transfer---tear paper---grinding is used.

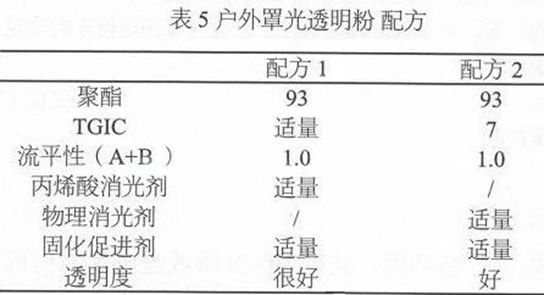

As a condition that the transparent transparent powder should have: 1 high transparency; 2 good leveling; 3 gloss meets requirements; 4 curing conditions meet the requirements of transfer wood grain ink.

In the above formula, the leveling agent can be mixed with two kinds to achieve the interlayer adhesion and transparency between the transparent powder and the base powder. The matting property can be selected with a type 68 chemical matting agent or a physical matting agent. After testing, type 68 The chemical matting agent is more transparent than the physical matting agent, and the amount of the matting agent is selected according to the gloss

In the above formula, the leveling agent may be selected from two kinds of mixing, in order to balance the interlayer adhesion and transparency between the transparent transparent powder and the base powder, and the matting property may be replaced by an acrylic instead of a matting agent or a physical matting agent. The matting agent is more transparent than the physical matting agent, and the amount of the matting agent is selected according to the gloss.

However, when the current material cannot produce a transparent powder with a gloss less than 50% or a gloss of less than 50%, the transparency is not ideal.

Due to the improvement of environmental protection requirements, it is inevitable to replace the oily clear coating with a transparent powder cover. However, due to the limitations of the current materials, it is not possible to produce a transparent powder which combines lower gloss, higher transparency and lower curing temperature. I hope that the more peers will have more targeted research, which is conducive to the development of the industry.